Self-Organized Nanoporous Alumina.

Influence of surface pre-treatment on the pore growth of nanoporous alumina at room temperature.

Nanoporous templates, such as anodic porous alumina, have gained much importance in the last 20 years due to their potencial industrial and technological applications for nanometric device fabrication. In fact, because the existent nano-lithographic techniques (e-beam. X-ray, focused ion beam) are expensive and have a low throughput, new assembling methods are needed for the large scale inexpensive production of nanodevices. Nanoporous anodic alumina templates, which can be readily obtained by common electrochemical processes, may be one such method for achieving the required nanodimensions. These templates can be used to obtain different nanomaterials such as nanodots, nanochannels or nanowires, showing their versatility of use. Furthermore, the fact that different ordered structures (hexagonal, square or triangular lattices) have been obtained by two step anodization and pre-patterning techniques, opens new possibilities for the applications of nanoporous anodic alumina.

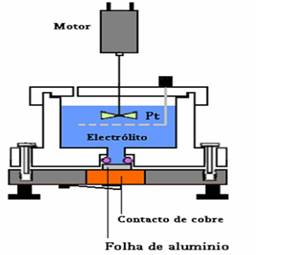

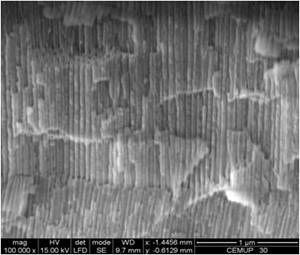

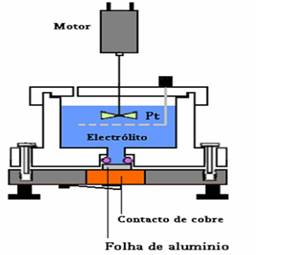

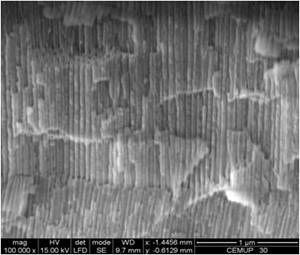

In this work we study how different pre-treatments (as-rolled, etanol degreasing, immersion in 1M NaOH for native oxide removal, diamond paste polishing, electropolishing and ion-milling etching) of high purity (99.997%) aluminum foils (prior to the first anodization step), influence pore growth and organization. Anodizations were carried out in 1.2 M H2SO4 for 1 hour, at room temperature. The current transients were monitored during anodization, allowing us to probe pore formation. After the first anodization we observed, using Scanning Electron Microscopy (SEM), the top of the anodized foil (alumina surface). The removal of this alumina layer allowed us to observe the pattern formed at the underlying aluminum surface. SEM images after the second anodization (under the same conditions as the first) were also performed. A comparative study of the influence in the porous structure of all pre-treatments will be shown and discussed.

Co antidot thin films deposited on nanoporous alumina templates.

Nanopatterned media, and in particularly magnetic arrays of nanodots and antidots, have gained increased attention in the last years. Due to the nonexistence of a superparamagnetic limit in antidot arrays they are strong candidates to be used as high density recording media. However, to achieve the desired submicron features, expensive techniques like electron beam or focused ion beam lithographies are usually required. An alternative is to use porous alumina templates, consisting of an ordered hexagonal lattice of nanoporous, as substrates for patterned film growth.

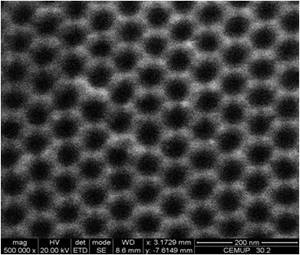

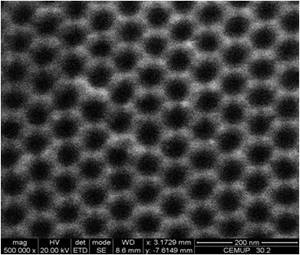

In this work we used ordered porous alumina substrates, obtained by a two-step anodization process of high purity (99.997%) aluminum foils, carried out in 0.3 M of H2SO4 at 10ºC. The current transients were monitored during anodization, allowing to probe pore formation. Scanning Electron Microscopy (SEM) revealed a long range order (1 umx1 um) of the hexagonal pore lattice with an average pore diameter of 30 nm. The ordeness of the pore distribution was characterized fast fourier transforms of the SEM pictures. We used highly ordered alumina templates as substrates to deposit, by Ion Beam Deposition, thin Co films in the 5 nm-50 nm thickness range. A magnetic field was applied during growth inducing an uniaxial anisotropy. Control samples of continuous films on a glass substrate allow a comparative study with the antidot system. We observed that complete pore closure occurs above a critical thickness of tCo~15 nm, however, the influence of the underlying pore structure on the coercivity of the thin films, as measured by Magneto-Optical Kerr Effect, remains up to a Co thicknesses of 25 nm, above which the films-on-template and the continuous control films exhibit similar magnetic properties. The enhanced coercivity is attributed to the domain wall pinning of the pore structure, as confirmed by high resolution Magnetic Force Microscopic measurements. The produced antidot arrays were also characterized by SEM, allowing us to obtain the size of the nanholes obtained.

Publications on progress.

Papers in international scientific periodicals with referees.

Influence of surface pre-treatment on the pore growth of nanoporous alumina at room temperature , C.T.Sousa, D.leitao,J. Ventura, A.M. Pereira, M. Amado, J.B. Sousa and J.P. Araújo Submitted to Solid State Physics.

Papers in proceedings:.

Nanoporous Self-organized Anodic ALumina Templates, C.T.Sousa, D.leitao,J. Ventura, A.M. Pereira, M. Amado, J.B. Sousa and J.P. Araújo Published in 8ºENCMP procedings, Lamego 2007 (Portugal).

Oral presentation.

Nanoporous Alumina nanoporosa: Templates para nanofabricação,D.C. Leitao, C. T. Sousa, J. Ventura, F. Carpinteiro, J.P. Araújo, M. Amado and J.B. SousaIII Jornadas do IFIMUP, Porto, 9 de Maio de 2007.

Posters.

Nanoporous Self-organized Anodic ALumina Templates, C.T.Sousa, D.leitao,J. Ventura, A.M. Pereira, M. Amado, J.B. Sousa and J.P. Araújo Presented in 8ºENCMP Lamego (Portugal).

Co Thin Films Deposited On Nanoporous Alumina Templates: from antidot arrays to continuous layer , C.T.Sousa, D.C.leitao,J. Ventura, F. Carpinteiro, M.M.Amado, J.B. Sousa and J.P. Araújo Presented in ESONN Grenoble .

Influence of surface pre-treatment on the pore growth of nanoporous alumina at room temperature , D.C.leitao,C.T.Sousa,J. Ventura, A.M. Pereira, M. Amado, J.B. Sousa and J.P. Araújo Presented in EMRS Fall Meeting, Warsow 2007.